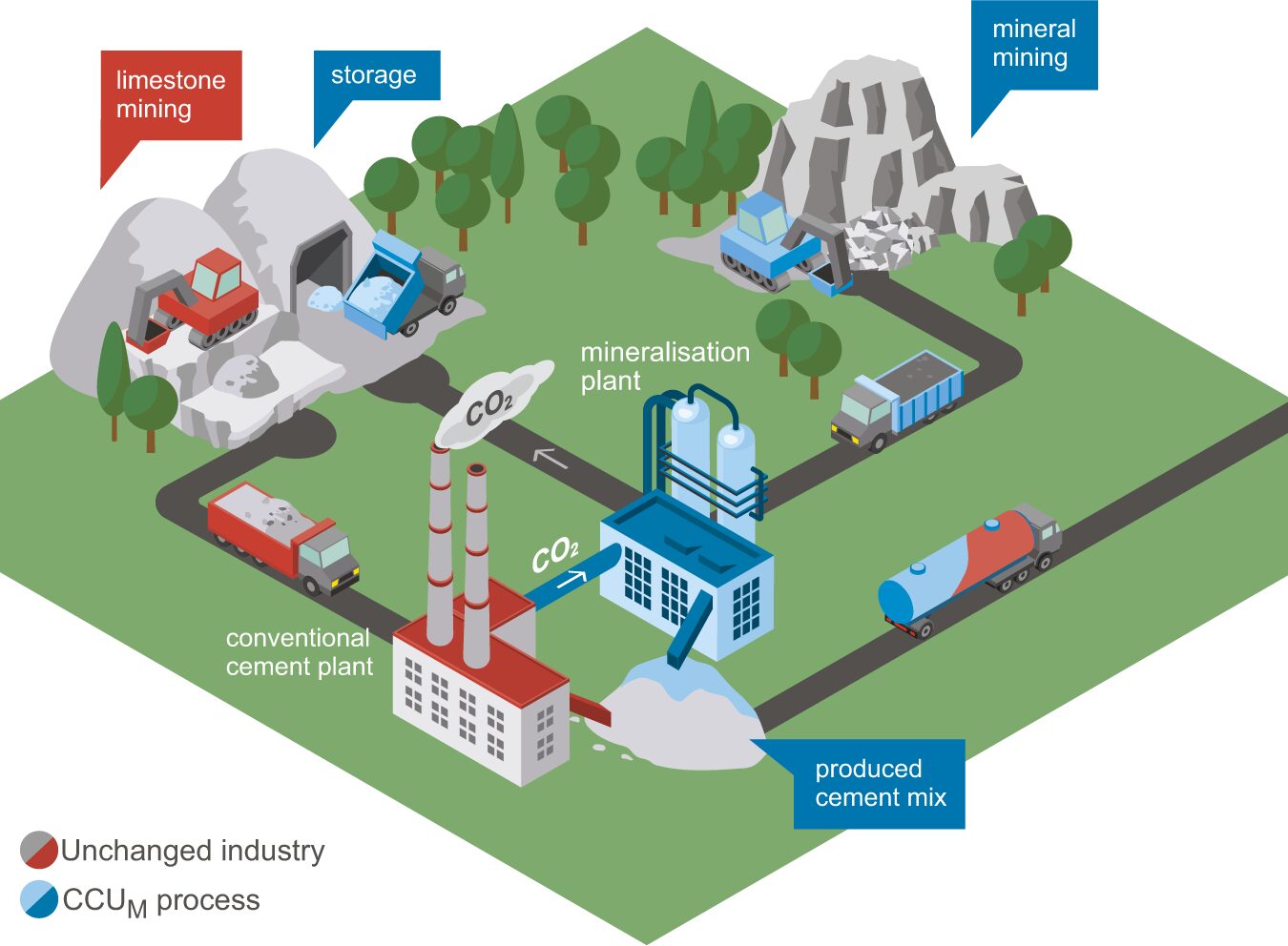

New cement technologies that mineralize CO₂ are advancing, but they only work at scale when the plant runs with efficient processes and low false air.

“Carbon-utilization” routes (injecting or mineralizing CO₂ into the material) and new no limestone clinker chemistries are maturing quickly. CarbonCure injects captured CO₂ into fresh concrete to permanently mineralize it; it reports more than 540,000 t of CO₂ saved as of 2025.

¿Que tecnologías hay?

The key technologies for CO₂-capturing/using cements fall into three complementary fronts: (1) CO₂ curing or activation—via injection or CO₂-rich atmospheres—which accelerates early carbonation and locks the gas into stable carbonates (e.g., approaches like CarbonCure); (2) alternative clinker chemistries to calcium carbonate that avoid limestone decarbonation and already show OPC-like performance, such as calcium-silicate–based routes (Brimstone), Ecocem’s ACT cements undergoing certification, and Sublime Systems scaling up with offtake agreements; and (3) waste mineralization, which re-carbonates fines and end-of-life cements with cost-effective abatement potential according to recent studies, forming a portfolio that reduces footprint without penalizing quality when plant operations are efficient.

¿Why process efficiency is the enabling condition?

These innovations only scale if the line is stable and efficient: less false air and good thermal control cut specific heat consumption and stabilize combustion, creating the operating window to introduce new curing routes/mixes without penalizing quality or productivity. OEMs and industry studies show savings of 5–10 kcal/kg clinker by optimizing separators/preheater and measurable reductions when tackling false air at kiln seals. In addition, less false air raises the CO₂ concentration in the gases, which also improves the viability of CCUS/CO₂-use schemes.

Cement accounts for ~7–8% of global emissions; the sector (GCCA/IEA) is pushing a net-zero roadmap that combines efficiency, alternative fuels, SCMs, CCUS, and new chemistries.

Fuentes: GCCA PNAS BrimstoneData Center DynamicsCenter for American ProgressEcocem+1S&P Global CarbonCure Technologies Inc.ScienceDirect