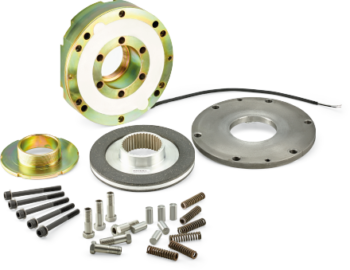

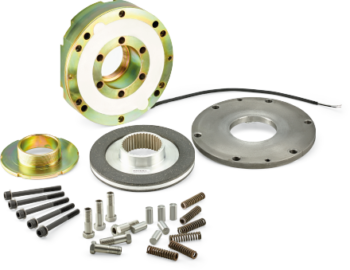

Motofrenos SAS has a flexible manufacturing system, producing special parts for brakes and clutches applications for industrial use; long and short formats.

Due to the industry’s current trend towards process automation and increased operational efficiency, electromagnetic brake and clutch systems have become essential elements in the manufacturing processes of goods and services.

Closed Brake Watch video

Open Brake Watch video

Clutch Brake Watch video

Due to the industry’s current trend towards process automation and increased operational efficiency, electromagnetic brake and clutch systems have become essential elements in the manufacturing processes of goods and services.

Closed Brake Watch video

Open Brake watch video

clutch Brake Watch video

The woven lining with copper insert operates in dry and wet applications and it is available in the following dimensions:

Width: Up to 20 inches

Thickness: From 3/16″ to 1 ½”

Length: Up to 10 meters.

The woven lining with cotton inserts only operates in dry applications and it is available in the following dimensions:

Width: 10 inches Width: 9 inches

Thickness: ½” Thickness: 3/8″

Length: 16.1 inches Length: 28 ½” inches.

The woven lining with cotton inserts only operates in dry applications and it is available in the following dimensions:

Width: 10 inches Width: 9 inches

Thickness: ½” Thickness: 3/8″

Length: 16.1 inches Length: 28 ½” inches.

The NON-woven lining with insertions of phenolic fibers, natural resins, and rubber only operates in dry applications and it is available in the following dimensions:

Width: Up to 6”

Thickness: From 3/16″ to ½”

Length: Up to 5 meters.

The material is available sheets of 1/8” to 1 ½” thickness.

In both materials, the copper insert allows a high coefficient of friction and temperature resistance, generating reliability in its operation, both in brake and clutch systems.

This material is only designed to operate in dry applications.

The material is available sheets of 1/8” to 1 ½” thickness.

In both materials, the copper insert allows a high coefficient of friction and temperature resistance, generating reliability in its operation, both in brake and clutch systems.

This material is only designed to operate in dry applications.

Remanufactured disks for oil immersed brakes are used in all types of heavy and agricultural machinery equipment. Its main benefit is represented by savings of up to 50% on the repair with the same performance as the original disk.

The SF friction plate is pre-molded, it has a groove that facilitates the flow of oil to cool down the brake system, thus allowing an optimal coefficient of friction, high performance, and low temperatures.

Toothed discs are also used for industry in general, especially in:

Clutches for mobile and stationary Diesel engines.

Irrigation pumps.

It is used in industrial machinery for transmission systems. It is not suitable for oil immersed applications.

Toothed discs are also used for industry in general, especially in:

Clutches for mobile and stationary Diesel engines.

Irrigation pumps.

It is used in industrial machinery for transmission systems. It is not suitable for oil immersed applications.